Horizontal Flow Wrap Machines: Costs & Operations Explained

In the modern packaging industry, the horizontal flow wrap machine has become an indispensable tool. Renowned for its efficient packaging and sealing capabilities, this machine provides protection and presentation for various products. This article delves into the workings of this advanced equipment, its ongoing operational costs, and other key considerations.

Introduction to the Horizontal Flow Wrap Machine

First and foremost, a horizontal flow wrap machine is an automated device designed specifically for packaging and sealing various products. These machines find applications across multiple sectors, including food, medical supplies, and cosmetics, among others, due to their efficiency, precision, and reliability.

The significance of these machines in the packaging industry is undeniable. They not only enhance production efficiency but also ensure product quality and consistency. When it comes to large-scale production and distribution, horizontal flow wrap machines are crucial in ensuring product safety and meeting market demands.

Working Principles of a Horizontal Flow Wrap Machine

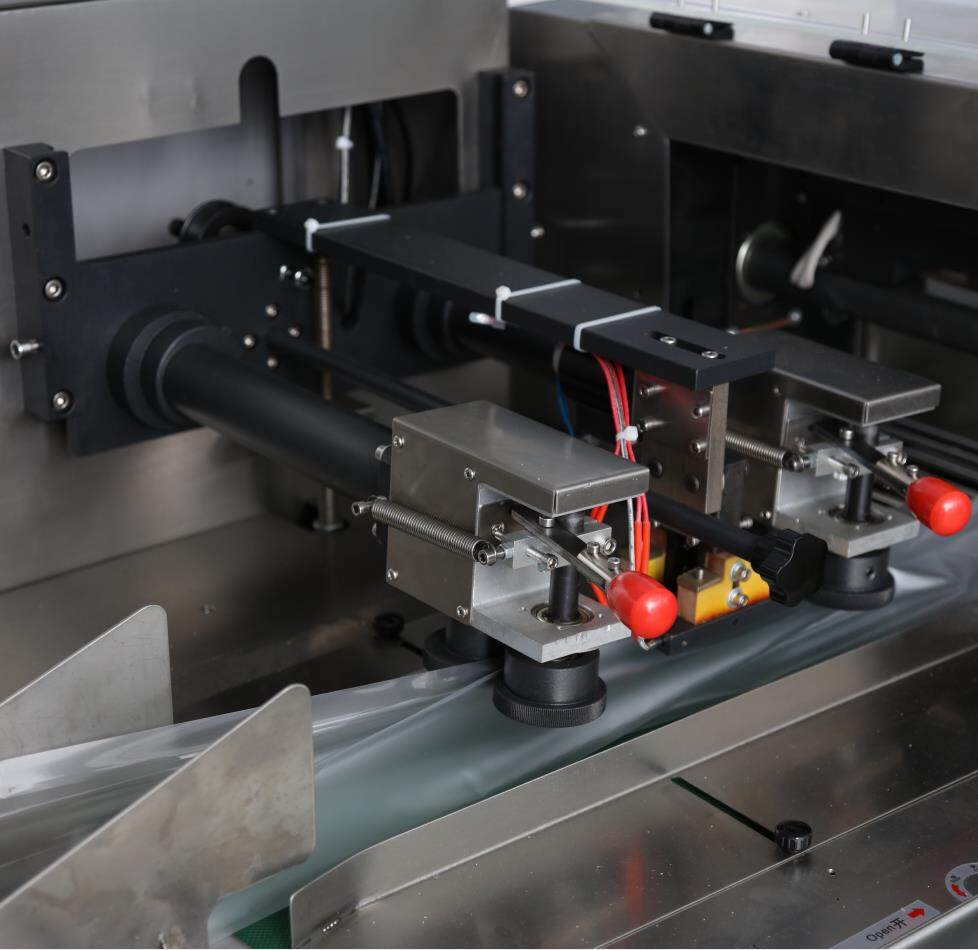

Understanding the working principles of the Horizontal Flow Wrap Machine requires insight into its primary components and operational processes. These machines employ automation systems to convey products from the feed-in port to the packaging area, subsequently performing sealing and cutting operations.

The typical workflow encompasses several steps:

1. product feeding and positioning.

2. Supply and cutting of packaging materials.

3. Packaging, sealing, and cutting of the products.

4. Ejection and collection of packaged products.

Through precise mechanical and electronic controls, horizontal flow wrap machines ensure each product is appropriately packaged and sealed, thereby elevating production efficiency and product quality.

Analysis of Ongoing Operational Costs

As businesses contemplate investing in horizontal flow wrap machines, understanding their ongoing operational costs becomes paramount. Beyond the initial purchase cost, enterprises need to account for:

Energy consumption: Operating these machines necessitates electricity, emphasizing the importance of energy efficiency and cost management.

Maintenance and parts replacement: Regular maintenance and replacement of parts are pivotal in ensuring the continuous optimal performance of the machines.

Labor and training costs: Operating and maintaining horizontal flow wrap machines require specialized skills and knowledge, thus necessitating training and labor costs.

By comprehensively analyzing these factors, businesses can evaluate the overall costs associated with horizontal flow wrap machines and make informed decisions.

Financing and Leasing Options

For businesses considering the purchase of horizontal flow wrap machines but concerned about initial investment costs, financing and leasing options offer flexible solutions. Various financing avenues, such as loans, installment plans, and equipment financing schemes, provide financial support, enabling businesses to spread costs and manage cash flow.

Furthermore, leasing horizontal flow wrap machines is also a viable option. Leasing not only reduces the initial investment but also offers flexibility, allowing businesses to adjust according to their needs.

Impact of Regulatory Standards and Compliance Requirements

When considering the pricing of horizontal flow wrap machines, regulatory standards and compliance requirements emerge as another crucial factor. Different industries and regions may have specific standards and regulations pertaining to product safety, quality control, and environmental protection.

Therefore, businesses need to closely monitor relevant regulatory changes and ensure their horizontal flow wrap machines comply with all applicable compliance requirements. This not only mitigates potential legal risks but also ensures market acceptance and credibility of products.

Maintenance Requirements and Long-Term Cost Analysis

Lastly, maintenance requirements and long-term cost analysis of horizontal flow wrap machines are pivotal in the decision-making process. Regular preventive maintenance and inspections can prolong machine lifespans, reduce failure rates, and enhance production efficiency.

Simultaneously, cost-benefit analysis of maintenance activities is indispensable. By evaluating the costs and benefits of different maintenance strategies, businesses can devise optimal maintenance plans, ensuring the long-term performance and reliability of horizontal flow wrap machines.

In conclusion, horizontal flow wrap machines play a crucial role in modern production environments. By gaining insights into their working principles, ongoing operational costs, financing options, compliance requirements, and maintenance needs, businesses can make informed investment decisions, ensuring the success and sustainability of their production activities.