High-Quality Long Stick Liquid Packing Machine Factory: Your Ultimate Guide

In the fast-evolving world of packaging, finding the right machinery is crucial to ensuring efficiency, quality, and cost-effectiveness. When it comes to liquid packaging, a high-quality long stick liquid packing machine factory can make all the difference. This blog aims to provide an in-depth look at what to consider when choosing a factory, the benefits of high-quality machines, and why investing in the right equipment is essential for your business.

Understanding Long Stick Liquid Packing Machines

What Are Long Stick Liquid Packing Machines?

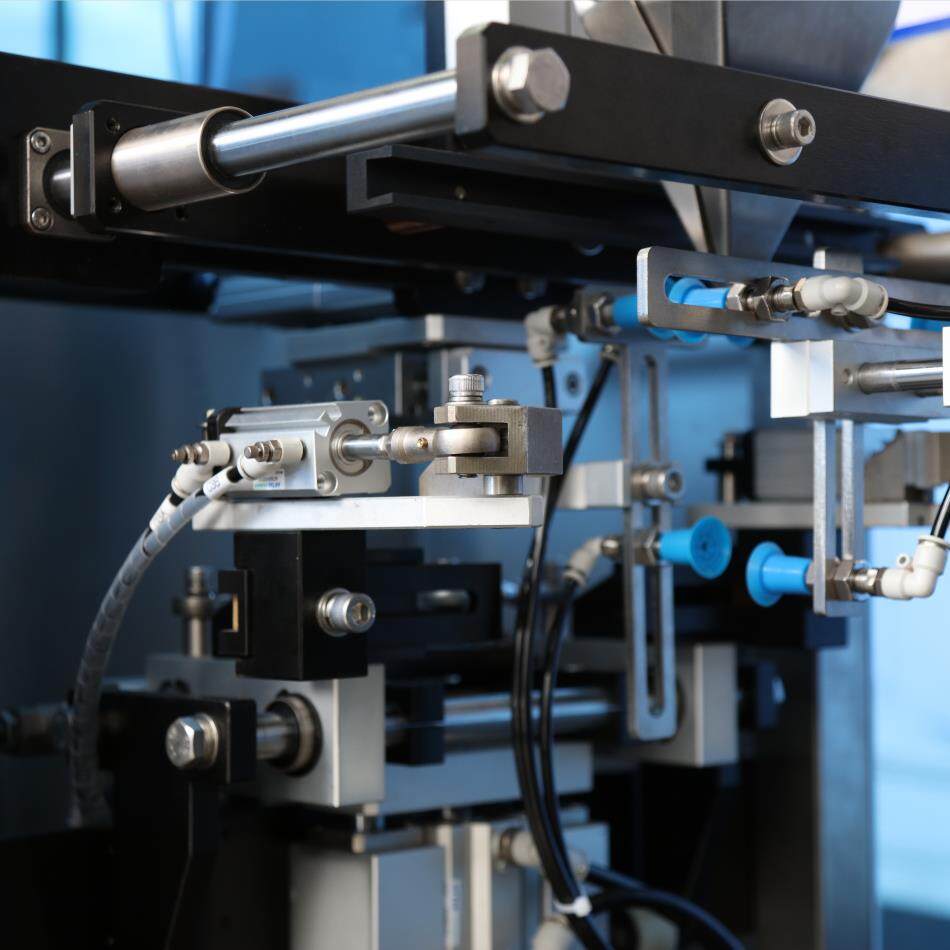

Long stick liquid packing machines are specialized equipment designed to package liquids in long, slender pouches or sticks. These machines are widely used in various industries, including food and beverage, pharmaceuticals, and cosmetics. The design allows for convenient and controlled dispensing, making it ideal for products like sauces, creams, gels, and even liquid supplements.

Key Features of High-Quality Machines

A high-quality long stick liquid packing machine factory produces machines that offer:

- Precision and Accuracy: Ensuring each stick is filled with the exact amount of liquid.

- Durability and Reliability: Built to last, reducing downtime and maintenance costs.

- Speed and Efficiency: Capable of high-speed production without compromising quality.

- Versatility: Able to handle various types of liquids and packaging materials.

- User-Friendly Interface: Easy to operate with minimal training.

Choosing the Right Factory

Factors to Consider

When selecting a high-quality long stick liquid packing machine factory, consider the following:

- Reputation and Experience: Look for factories with a proven track record in the industry.

- Technological Advancements: Factories that invest in the latest technology often produce superior machines.

- Customer Support: Reliable after-sales service and technical support are crucial.

- Customization Options: The ability to customize machines to meet specific needs.

- Compliance with Standards: Ensure the factory adheres to international quality and safety standards.

Top Global Manufacturers

Some of the leading manufacturers in the industry include:

- Bosch Packaging Technology: Known for innovative and high-quality packaging solutions.

- Tetra Pak: A pioneer in liquid packaging with a focus on sustainability.

- Marchesini Group: Specializes in pharmaceutical and cosmetic packaging machines.

Benefits of Investing in High-Quality Machines

Enhanced Productivity

High-quality long stick liquid packing machines can significantly boost your production rates. Their advanced technology allows for faster and more efficient packaging, reducing bottlenecks and downtime.

Cost Savings

While the initial investment might be higher, the long-term benefits of reduced maintenance, lower downtime, and higher efficiency lead to substantial cost savings.

Improved Product Quality

Precision in filling ensures consistent product quality, which is vital for customer satisfaction and compliance with industry standards.

Flexibility and Scalability

High-quality machines offer the flexibility to handle various products and packaging sizes, allowing your business to adapt and grow with market demands.

Case Studies and Success Stories

Case Study: XYZ Beverage Company

XYZ Beverage Company invested in high-quality long stick liquid packing machines from a renowned factory. The result? A 30% increase in production efficiency, a significant reduction in packaging errors, and enhanced product quality. This investment enabled XYZ to expand their product line and enter new markets.

Success Story: ABC Pharmaceutical

ABC Pharmaceutical needed a reliable solution for packaging their liquid supplements. After extensive research, they chose a high-quality long stick liquid packing machine factory known for its expertise in the pharmaceutical sector. The new machines not only improved their packaging process but also ensured compliance with stringent industry regulations.

Future Trends in Liquid Packaging

Automation and AI Integration

The future of liquid packaging lies in automation and artificial intelligence. High-quality long stick liquid packing machine factories are increasingly incorporating AI to enhance precision, reduce waste, and optimize production processes.

Sustainable Packaging Solutions

With the growing emphasis on sustainability, factories are developing machines that can handle eco-friendly packaging materials. This shift not only meets consumer demands but also aligns with global environmental goals.

Industry 4.0 and IoT

The integration of Industry 4.0 and the Internet of Things (IoT) in packaging machines is revolutionizing the industry. Real-time monitoring, predictive maintenance, and data analytics are becoming standard features, enabling better decision-making and operational efficiency.

How to Maintain Your Packing Machines

Regular Maintenance Tips

- Routine Inspections: Regularly check for wear and tear to prevent unexpected breakdowns.

- Proper Cleaning: Keep the machines clean to avoid contamination and ensure smooth operation.

- Lubrication: Regularly lubricate moving parts to reduce friction and wear.

- Software Updates: Ensure the machine’s software is up-to-date to benefit from the latest features and improvements.

Troubleshooting Common Issues

- Filling Inconsistencies: Check the filling nozzles and calibration settings.

- Machine Jams: Inspect for blockages and ensure proper alignment of packaging materials.

- Electrical Issues: Verify connections and consult the factory’s technical support if needed.

Conclusion

Investing in a high-quality long stick liquid packing machine factory is a strategic decision that can propel your business to new heights. From enhanced productivity and cost savings to improved product quality and future-proofing your operations, the benefits are manifold. By considering the factors outlined in this guide, you can make an informed choice and partner with a factory that meets your specific needs.